¿QUÉ ESTÁS BUSCANDO?

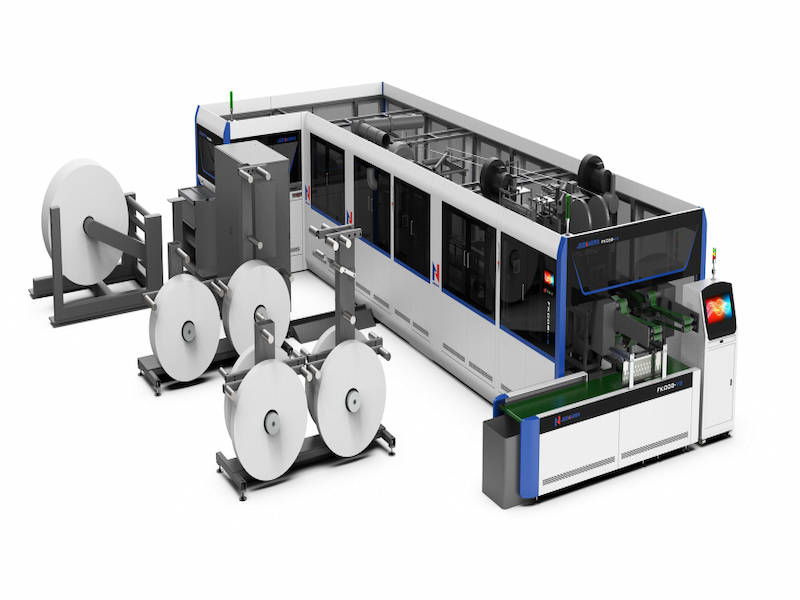

El muy esperado FK008 de tercera generación se lanzará en enero de 2025. Gachn Group mostrará la nueva máquina de bolsas de válvulas en el Exposición de Egipto.

| Comparación de máquinas de fabricación de bolsas de válvulas antiguas y nuevas | |||

| NO. | Contenido de comparación | Máquina vieja | Nueva máquina |

| 1 | Velocidad de arranque estable | 120 piezas/min | Actualización de velocidad: la velocidad de funcionamiento estable puede alcanzar 130 bolsas/minuto, y hasta 140 bolsas/minuto, alta velocidad y estabilidad, creando más beneficios para las empresas. |

| 2 | Velocidad de la máquina inactiva | 130 piezas/min | |

| 4 | Distancia central del fondo de la bolsa terminada | 370 ~ 750 mm; Si se calcula en función de 80 inferior, la longitud mínima de la bolsa terminada es de 470 mm | Servo Control ajusta las especificaciones con un botón, que es más inteligente y más conveniente. Las especificaciones de fabricación de bolsas se amplían aún más, y el ancho aplicable puede ser tan bajo como 300 mm, lo que admite soluciones personalizadas de más tamaños. |

| 6 | Función de inspección visual | Ninguno | Actualización visual: la función de inspección visual de IA es más potente, admite múltiples soluciones de inspección, como impresión, tela base, defectos de bolsas y soporte de personalización más personalizada. |

| 7 | Rodillo de alimentación del mecanismo de brazo oscilante | Versión antigua del diseño de Roller de Feed | Estructura de alimentación actualizada: diseño de rodillos de alimentación y rodillo de goma más avanzados, reduciendo los costos de mantenimiento y mejorando la eficiencia operativa. |

| 8 | Tracción del brazo oscilante y rodillo de goma de alimentación de bolsas | Versión antigua del diseño de rolleros de goma | |

| 10 | Mecanismo de corte de bolsas | No se puede ensamblar de forma independiente | Proceso de ensamblaje optimizado: diseño avanzado de ensamblaje, mejora de la precisión del ensamblaje y mejora de la estabilidad del equipo. |

| 11 | Cola presionadora de bolsas | Diseño de cola de presión vertical | Diseño de ángulo: reduzca el riesgo de transferencia de sección de la bolsa, diseño innovador del proceso, evite el impacto de la transferencia de la bolsa y proporcione una mayor estabilidad. |

| 12 | Transferencia de bolsas | Transferencia de bolsa de succión, piezas un poco más vulnerables | Actualización de la estructura de fabricación de bolsas: optimice aún más el diseño estructural, reduzca las piezas de uso y mejore la durabilidad. Diseño más modular, mantenimiento más conveniente, menos artículos de mantenimiento |

| 13 | Estructura de cambio de bolsa | Modo de rotación interno y externo | Actualización del mecanismo de cambio de bolsa: ajuste automático de acuerdo con los cambios de ancho de la bolsa, no es necesario modificar los parámetros, simplificar los pasos de depuración y responder rápidamente. Reduzca los costos de mantenimiento y mejore la eficiencia operativa. |

| 14 | Mecanismo de guía de formación | Cinturón múltiple [22 mm] | Ampliar el mecanismo de la guía de formación: reduzca la situación de la asimetría del triángulo, mejore la estabilidad de la apertura de la bolsa y mejore la calidad del producto |

| 15 | Ajuste automático de marco | Ninguno | El marco está equipado con un motor de frecuencia variable y un posicionador, que se puede ajustar automáticamente, por lo que es más conveniente y más rápido para los operadores cambiar los números, reduciendo el tiempo de operación del personal de producción |

| 16 | Número total de servos | Un total de 30 servos de eje en la máquina antigua | Aplicación de un sistema de servo eficiente: el nuevo diseño reduce significativamente el consumo de energía, mejora la conveniencia de la operación y la experiencia del usuario, la gestión inteligente de las pistolas de aire caliente y la aplicación y la gestión inteligente de los servo sistemas muestran las ventajas de la eficiencia y la calidad de la producción. |

| 21 | Mecanismo de protección | Perfil de aluminio + mascota | Actualización de apariencia: el nuevo apariencia de diseño estético industrial es simple y atmosférico, con practicidad y facilidad de uso, más en línea con los conceptos estéticos modernos y destaca la armoniosa coexistencia de la artesanía y la textura. |