¿QUÉ ESTÁS BUSCANDO?

Nombre del producto :

Gachn IntelliGreen PackUnitNúmero de artículo :

GC-850-6SOrden (MOQ) :

1Pago :

30% advance payment, 70% balance before shipment or negotiableOrigen del producto :

xiamen,chinaPuerto de embarque :

XIAMEN or Or according to your needsPlazo de entrega :

3 monthsGachn Group es una empresa de alta tecnología empresa wCon capacidades de I+D completamente independientes, se centra en la I+D y la producción de soluciones de equipos para cemento y se compromete a brindar a sus clientes globales servicios integrados y eficientes para la producción, el envasado y el transporte de cemento. La empresa cuenta con más de 14 años de experiencia en el sector y ha establecido un equipo de I+D de más de 100 ingenieros senior. Gracias a su sólida experiencia técnica y a su capacidad de innovación, continúa superando las dificultades técnicas en la producción de cemento, ayudando a sus clientes a optimizar los procesos de producción y a mejorar su competitividad en el mercado.

Ventajas y aplicaciones del producto

1. Actualización de la automatización, rediseñando la eficiencia de la producción

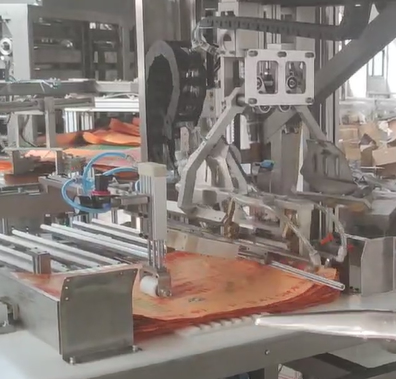

La máquina de inserción de bolsas del grupo Gachn reemplaza el método manual tradicional de inserción de bolsas con un funcionamiento totalmente automatizado, mejorando significativamente la eficiencia del envasado de cemento, reduciendo los costos de mano de obra y las tasas de desperdicio. Sus funciones principales incluyen:

Operación colaborativa eficiente: un solo operador puede administrar de 3 a 5 dispositivos en la misma área de plataforma y cooperar con la máquina envasadora de cemento rotatoria para completar automáticamente todo el proceso de alimentación de bolsas, inserción de bolsas, llenado y costura de bolsas.

Protección del medio ambiente y la salud: reducir los riesgos para la salud del polvo de cemento para los trabajadores, mejorar el entorno de trabajo y reducir el consumo de energía y la contaminación ambiental.

2. Tecnología líder, excelente rendimiento.

Control preciso: Servomotor Schneider y sistema de control PLC, combinado con interfaz hombre-máquina de pantalla táctil, para lograr un control de movimiento de alta precisión y monitoreo en tiempo real, para satisfacer la alta demanda de producción de 120 toneladas/hora.

Adaptación flexible: El equipo admite un diseño personalizado, puede ajustar la capacidad del contenedor de bolsas, la posición del mecanismo de empuje de bolsas y el ángulo de apertura de la bolsa de acuerdo con los requisitos de la línea de producción y adaptarse a diferentes especificaciones de bolsas de embalaje (como una plataforma de almacenamiento de bolsas de 4 metros de largo).

Estable y duradero: los componentes principales se seleccionan de marcas de renombre internacional (como rodamientos NSK, cilindros SMC, componentes eléctricos Schneider) para garantizar un funcionamiento estable a largo plazo del equipo con costos de mantenimiento extremadamente bajos.

Especificaciones técnicas y configuración

1. Parámetros del equipo

Dimensiones y peso: El tamaño de la máquina principal es de 5,5 m × 3,0 m × 2,2 m (ajustable) y la máquina completa pesa aproximadamente 2300 kg.

Requisitos de energía: Fuente de alimentación trifásica 380 V CA ± 5 %, la potencia total de la máquina es de aproximadamente 10 kW; presión de la fuente de gas ≥0,5 MPa (tanque de gas estándar de 20 L).

Capacidad: Velocidad máxima de procesamiento 120 toneladas/hora, tasa de éxito de inserción de bolsas ≥99%.

2. Configuración de componentes principales

Sistema eléctrico: Servoaccionamiento Schneider, relé de seguridad Omron, sensor Panasonic, para garantizar un control preciso y un funcionamiento seguro.

Estructura mecánica: reductor SHIMPO, acoplamiento KTR, riel guía HIWIN, para lograr una transmisión y posicionamiento de alta confiabilidad.

Módulo funcional:

Empujador de bolsas: plataforma de límite de tres lados, soporte de colocación de bolsas asistida manualmente;

Extractor de bolsas: diseño de transición único para garantizar un movimiento suave de las pilas de bolsas;

Apertura de bolsa: sistema de ventosa y gancho adaptable, monitoreo en tiempo real de la presión de vacío, se adapta a diferentes tipos de bolsas.

Servicio y soporte posventa

El grupo Gachn se basa en el "servicio de ciclo completo" para brindar a sus clientes una protección integral:

Personalización previa a la venta: planificar el flujo del proceso según las necesidades del cliente y brindar soluciones de selección y diseño de equipos.

Capacitación en instalación: personal técnico destacado en la fábrica para guiar la puesta en servicio, operación y resolución de problemas del equipo para garantizar una producción rápida.

Garantía postventa: 1 año de garantía para toda la máquina, reparación o reemplazo gratuito de piezas debido a defectos de diseño o fabricación;

Actualizaciones de software gratuitas y soporte técnico dentro de los 3 años;

Mecanismo de respuesta de 24 horas para minimizar las pérdidas por tiempo de inactividad.

Perspectivas de la industria: La inteligencia lidera el futuro

A medida que la industria cementera se transforma hacia la inteligencia y la sostenibilidad, la insertadora de sacos del grupo Gachn optimiza aún más la autoinspección de los equipos, la monitorización del consumo energético y las funciones de operación y mantenimiento remotos mediante la integración de algoritmos de IA y tecnologías del Internet de las Cosas. En el futuro, la empresa seguirá profundizando sus raíces en el campo de la automatización, dotando a sus clientes de tecnologías innovadoras y promoviendo el desarrollo eficiente y sostenible de la industria cementera global.