¿QUÉ ESTÁS BUSCANDO?

En toda la cadena de suministro de envases industriales, elegir el formato adecuado es fundamental, mientras que el uso eficaz de equipos inteligentes es clave para impulsar la competitividad. Ya se trate de bolsas flexibles y económicas con ranuras en espiral o bolsas eficientes y herméticas con ranuras de válvula, combinarlas con equipos profesionales de fabricación de bolsas inteligentes logra un ciclo completo de reducción de costes, mejora de la calidad y optimización de la eficiencia. Hoy, le mostraremos dos máquinas de fabricación de bolsas líderes en la industria:Máquina para fabricar bolsas con ranuras de válvula con inspección por visión de IA de Gachn Group y máquina de embolsado y ranurado de bobinas de alta velocidad GM051 de Gachn Group—¡y vea cómo brindan soluciones óptimas para diversas necesidades de embalaje!

Ⅰ.Actualización de la producción de bolsas de válvulas: La Máquina para fabricar bolsas con inspección por visión artificial del Grupo Gachn 3.0 ofrece tanto eficiencia como precisión.

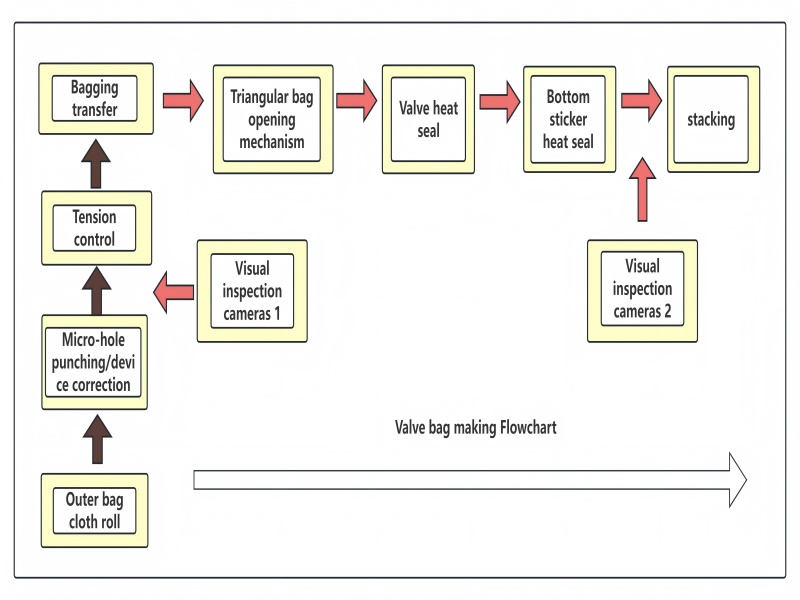

(Diagrama del proceso de funcionamiento de la máquina para fabricar bolsas de válvula del grupo Gachn)

Las bolsas de válvula, gracias a sus sólidas propiedades de sellado y su alta adaptabilidad a la automatización, se han convertido en la opción preferida en industrias como la cementera, la química y la de polvos minerales. Sin embargo, los procesos de producción tradicionales siguen afectando a las empresas con una baja eficiencia en la selección manual de bolsas, altas tasas de desperdicio y un control de costos complejo. La máquina 3.0 de Gachn Group para fabricar bolsas de válvula con inspección visual basada en IA soluciona estos problemas con innovación tecnológica.

Los aspectos tecnológicos más destacados redefinen los estándares de producción de bolsas de válvula.

1. Inspección visual con IA reemplaza la inspección manual.

El sistema estándar de inspección visual de materia prima utiliza cámaras de alta precisión y algoritmos de IA para identificar automáticamente defectos como agujeros, empalmes y desviaciones de urdimbre y trama en la tela base, así como esquinas torcidas, etiquetas inferiores descentradas y solapamientos deficientes en las bolsas terminadas, con una tasa de rechazo de tan solo el 0,05 %. Esto elimina la necesidad de uno o dos operarios de selección de bolsas por línea de producción, solucionando por completo los problemas de la industria relacionados con la dificultad de contratación y la inspección de calidad inconsistente.

2. Totalmente controlado por servomotor, ofreciendo velocidad y flexibilidad.

La máquina ofrece una velocidad de operación estable de 120 a 130 bolsas por minuto, superando ampliamente a los equipos tradicionales. Permite cambiar de tamaño con un solo clic, alternando fácilmente entre varios tamaños, incluyendo 380-910 mm (ancho de la bolsa tejida) y 80-200 mm (longitud del puerto de la válvula), eliminando la compleja depuración y aumentando la flexibilidad en la producción por lotes. Reducción visible de costos y aumento de la eficiencia.

Utilizando tecnologías como la laminación a una sola cara y la reducción del ancho de solapamiento, los clientes pueden ahorrar cientos de miles de yuanes en costos de material al año. Una tasa de desperdicio de tan solo el 0,1 % minimiza la pérdida de materia prima.

3. Servicio postventa sin preocupaciones y empoderamiento continuo.

Brindamos instalación y puesta en marcha en el sitio, capacitación profesional para operadores y actualizaciones gratuitas del sistema de control electrónico dentro de los tres años para garantizar que el equipo mantenga un rendimiento líder en la industria.

Aplicaciones aplicables: El sellado es esencial en sectores que van desde los materiales de construcción hasta los productos químicos.

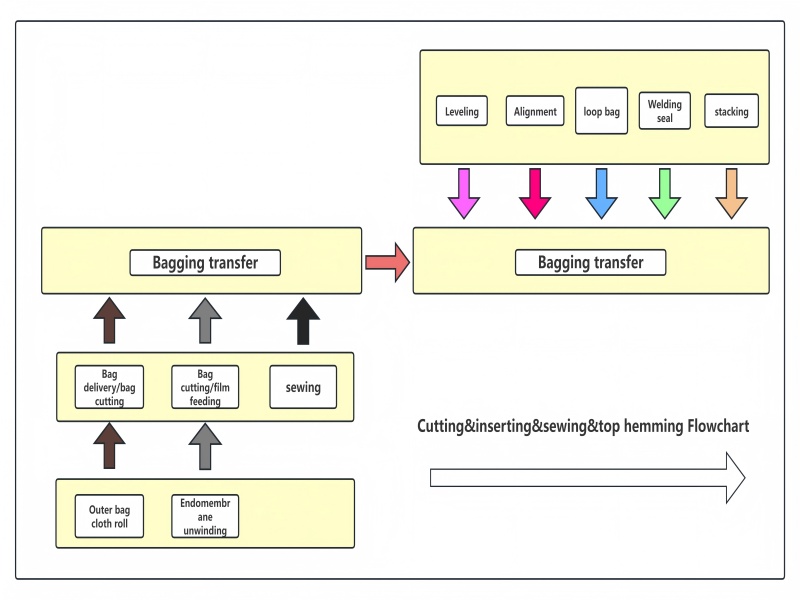

Diagrama de flujo de trabajo de la máquina de corte, inserción, costura y dobladillado superior del grupo Gachn

Prevención de fugas de polvo en materiales de construcción polvorientos, como cemento, yeso en polvo y masilla en polvo.

Protección contra la humedad y la contaminación en productos que requieren altas propiedades de sellado, como polvos químicos finos y pigmentos.

Adecuado para líneas de llenado automatizadas de polvos a granel como polvo mineral y polvo de carbón.

Ⅱ. Aceleración de la producción de bolsas de bucle: La máquina embolsadora y de bucle de alta velocidad GM051 de Gachn Group combina flexibilidad y eficiencia.

Las bolsas de bucle son conocidas por su facilidad de uso y rentabilidad, lo que las hace ampliamente utilizadas en las industrias de granos, piensos y alimentos. Sin embargo, los procesos de producción tradicionales se ven afectados por procesos fragmentados, bajas velocidades y frecuentes intervenciones manuales, lo que dificulta la producción a gran escala. Máquina de envasado y sellado de alta velocidad GM051 de Gachn Group utiliza un proceso totalmente automatizado para realizar una transición eficiente del rollo de tela a la bolsa terminada.

Los aspectos más destacados de la tecnología central hacen que la producción de bolsas de bucle sea más inteligente.

Los procesos totalmente automatizados reducen la intervención manual. Desde el desenrollado de la bolsa exterior, la envoltura interior con film y la costura de la cola de la bolsa hasta la formación de bucles, la soldadura ultrasónica de los labios y el apilado automático, todo el proceso está controlado por un PLC y un servoaccionamiento, eliminando la necesidad de operación manual. Una pantalla táctil de 10 pulgadas proporciona control gráfico, lo que simplifica e intuitivo el ajuste de parámetros.

1. Proceso de transporte continuo, aumentando la velocidad en un 30%.

El innovador diseño de "mecanismo que sigue a la bolsa" reduce los tiempos de arranque y parada de la bolsa, logrando una velocidad de operación estable de 30 bolsas/min. La bolsa exterior y la película interior están alineadas con precisión (error de longitud ≤ ±5 mm), lo que garantiza una soldadura fiable y uniforme, y una calidad del producto final más consistente.

2. Compatible con múltiples especificaciones para satisfacer diversas necesidades.

Compatible con longitudes de bolsa exterior de 650-1100 mm, anchos de 500-650 mm y espesores de película interior de 0,015-0,05 mm, satisface fácilmente las necesidades de envasado de diversos materiales, como arroz, frijoles y pienso. Compatible con bolsas M y bolsas planas para una mayor flexibilidad.

3. Calidad detallada y máxima durabilidad.

Utilizando componentes de alta calidad, como servomotores Schneider importados de Alemania y acoplamientos KTR alemanes, la base del bastidor utiliza tubos cuadrados con un espesor de pared de ≥6 mm, y los paneles de pared principales tienen un espesor de ≥15 mm, lo que garantiza un funcionamiento estable a largo plazo. Las características de seguridad, como la detección de rotura de cable y la protección de parada de emergencia, garantizan una mayor tranquilidad durante la producción.

Escenarios aplicables: Necesidades de embalaje flexible para alimentos y agricultura.

Para el envasado doméstico y mayorista de alimentos como arroz, granos y frijoles, el diseño de anillo permite un fácil acceso.

Para materiales granulares agrícolas, como alimentos y semillas, el proceso de película y soldadura proporciona resistencia a la humedad y al polvo.

En el caso de materias primas industriales como los gránulos de plástico, la producción en masa eficiente reduce los costos de embalaje.

¿Cómo elegir? Busca el modelo perfecto según tus necesidades.

Si está produciendo bolsas de válvulas y requiere alta velocidad, pocos desechos y mano de obra reducida, elija la Máquina para fabricar bolsas con inspección visual por IA de Gachn Group 3.0Es especialmente adecuado para empresas de materiales de construcción y productos químicos de gran escala y de altos estándares.

Si se centra en bolsas de bucle y requiere una adaptación flexible a múltiples especificaciones y una automatización completa del proceso, elija la Máquina de corte y bucle Gachn Group GM051. Es ideal para industrias como la alimentaria y la agrícola, donde la facilidad de uso es primordial.

Ya sea el sellado eficiente de las bolsas de válvula o la flexibilidad y practicidad de las bolsas de bucle, Grupo GachnImpulsada por su misión de "Desbloquear tecnologías clave y crear valor para el cliente", ofrece soporte durante todo el ciclo de vida, desde el equipo hasta el servicio. Contáctenos para una consulta y recibir soluciones personalizadas de fabricación de bolsas, ¡haciendo que la producción de envases sea más inteligente y sin preocupaciones!