¿QUÉ ESTÁS BUSCANDO?

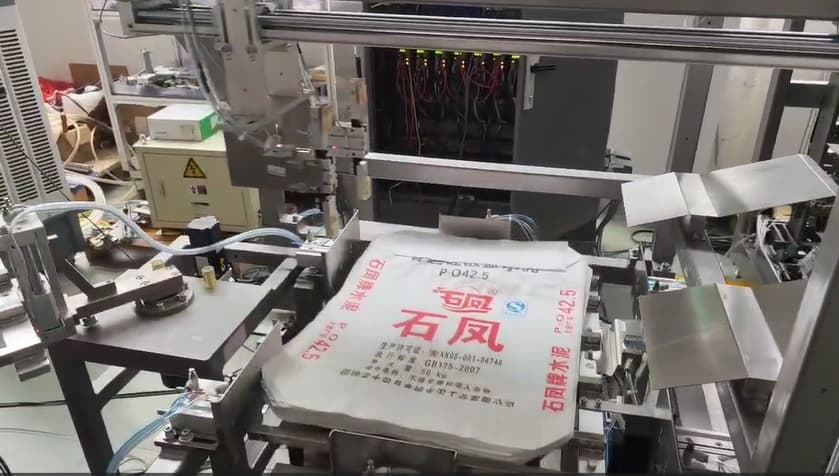

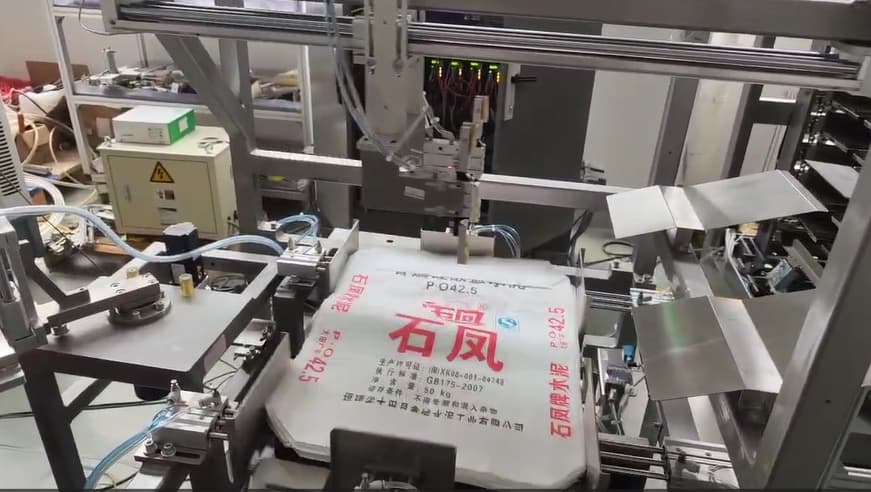

La máquina insertadora de bolsas de cemento totalmente automática del grupo Gachn es un equipo eficiente e inteligente diseñado para líneas de producción de cemento, que integra automatización, alta precisión y alta estabilidad.

Nombre del producto :

Cement Bag Pro-InsertorNúmero de artículo :

GC-850-6SOrden (MOQ) :

1Pago :

30% advance payment, 70% balance before shipment or negotiableOrigen del producto :

xiamen,chinaPuerto de embarque :

XIAMEN or Or according to your needsPlazo de entrega :

3 monthsPro-Insertor de bolsas de cemento

La máquina insertadora de sacos de cemento totalmente automática del grupo Gachn es un equipo eficiente e inteligente, diseñado para líneas de producción de cemento, que integra automatización, alta precisión y alta estabilidad. Gracias a su avanzada tecnología de servocontrol y sistemas inteligentes, este equipo puede reemplazar por completo las operaciones manuales tradicionales, mejorar significativamente la eficiencia del envasado, reducir los daños causados por la contaminación por polvo al personal y ayudar a las cementeras a lograr una producción ecológica y eficiente.

1. Principales ventajas técnicas

Proceso totalmente automatizado

Logre la automatización de todo el proceso desde la clasificación de bolsas, el empuje de bolsas, la apertura de bolsas hasta la inserción de bolsas, con una tasa de éxito única de inserción de bolsas de ≥99% y un aumento en la capacidad de producción de más del 30%.

Equipado con sensores inteligentes y servomotores, controla con precisión la trayectoria del movimiento para garantizar que las bolsas de embalaje estén intactas y el embolsado sea preciso.

Diseño inteligente modular

Piezas de clasificación de bolsas: adoptan tecnología de elevación y soporte de bolsas, sacudidas de bolsas y palmaditas de bolsas para reducir la fricción entre las bolsas y garantizar un apilado ordenado de las bolsas.

Piezas de apertura de bolsa: El sistema de ventosa y gancho con curvatura de superficie de bolsa adaptable admite el monitoreo de la presión de vacío en tiempo real y la estabilidad de apertura de la bolsa alcanza el nivel líder en la industria.

Piezas de inserción de bolsas: Componentes de sujeción de bolsas servoaccionados, que pueden ajustar de manera flexible la curva de movimiento y adaptarse a una variedad de especificaciones de empaque.

Alta compatibilidad y flexibilidad

La capacidad del contenedor de bolsas se puede personalizar (plataforma de almacenamiento estándar de 4 metros, con capacidad para 500 bolsas), admitiendo bolsas de diferentes tamaños (largo × ancho × alto: 6900 × 4700 × 2050 mm).

La parte inferior del equipo está equipada con un dispositivo de ajuste horizontal para adaptarse a la disposición de varios escenarios de producción.

Configuración internacional de primera clase

Sistema eléctrico: Controladores y componentes de seguridad de marcas Schneider, Omron y otras para garantizar un funcionamiento estable y confiable.

Piezas mecánicas: reductor Xinbao de Japón, acoplamiento KTR de Alemania, riel guía HIWIN de Taiwán, etc., para garantizar una larga vida útil y una baja tasa de fallas del equipo.

2. Perspectivas del mercado y valor de la inversión

La demanda de la industria aumenta

La industria mundial de la construcción se está desarrollando rápidamente y la demanda de cemento sigue creciendo. Se prevé que el mercado mundial del cemento superará los 46.850 millones de dólares estadounidenses en 2029, impulsando simultáneamente la expansión del mercado de insertadores de bolsas.

Con la aceleración de la apertura del comercio internacional, la demanda de equipos de automatización en los mercados extranjeros ha aumentado significativamente, creando un amplio espacio para las exportaciones de productos.

Reducción significativa de costes y aumento de la eficiencia

La producción totalmente automatizada puede ahorrar más del 80% en costos laborales, al tiempo que reduce el desperdicio de material y los costos integrales entre un 20% y un 30%.

La vida útil del equipo es de más de 10 años, con bajos costos de mantenimiento y un ciclo de retorno de la inversión corto.

Ventajas competitivas excepcionales

En la feroz competencia del mercado, la insertadora de bolsas del grupo Gachn se destaca por su alta precisión, diseño inteligente y modular, ayudando a las empresas a mejorar su imagen de marca y el valor agregado de su producto.

A través de la innovación tecnológica y la optimización del servicio al cliente, ayuda a las empresas cementeras a establecer puntos de referencia de la industria en múltiples dimensiones, como la protección del medio ambiente, la eficiencia y la calidad.

3. Resumen de parámetros técnicos

| Proyecto | Presupuesto |

| Tamaño de la máquina | L5,5 m × An3,0 m × Al2,2 m (diseño personalizable) |

| Potencia de la máquina | Aproximadamente 10KW (fuente de alimentación: 3Ph 380Vac ± 5%, 50Hz) |

| Requisitos de la fuente de aire | Presión de aire ≥0,6 MPa, tanque de gas estándar de 20 L |

| Tipo de bolsa aplicable | Varios tamaños (admite longitud de plataforma de caché personalizada) |

| Marca del componente principal | Marcas internacionales como Schneider, Omron, Xinbao, HIWIN, etc. |

4. Escenarios de aplicación

Línea de producción de cemento: conexión perfecta con el equipo de llenado para lograr un funcionamiento continuo de alta velocidad.

Centro de almacenaje y logística: adecuado para el paletizado y transporte automatizado de cemento ensacado.

Proyectos internacionales: cumplir con los estrictos estándares para equipos de alta precisión en Europa, América, el Sudeste Asiático y otras regiones.

La insertadora de sacos de cemento totalmente automática del grupo Gachn se basa en tecnología de vanguardia, alta eficiencia y fiabilidad, y ofrece soluciones de actualización inteligentes para empresas cementeras globales. Invertir en el grupo Gachn no se trata solo de elegir un equipo, sino también de una estrategia para aprovechar las futuras oportunidades del mercado.